|

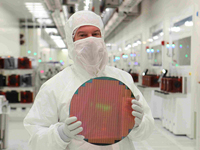

Kinematic Applications for the Semiconductor Industry

When used to assemble system component "A" onto system component "B", kinematic mounts provide four main underlying benefits:

- Docking Manipulators A docking manipulator is any tool that is brought into position by a robotic arm, but requires further mechanical registration to the workpiece or workstation. This "docking" registration provides extremely high accuracy (<.0001") and very high rigidity at the docking point. Our 4-legged mounts allow very elegant docking of large rectangular tools and tooling frames.

- Interchangeable tooling With extremely high repeatability and rigidity, a three-legged kinematic mount is perfect for imlementing a tool interchange interface.

- AGV positioning Depending on the form-factor of the AGV (round or rectangular), a 3-legged or 4-legged kinematic mount enables the AGV to "kneel" on top of a kinematic mount for a rigid and precise work posture.

- Workpiece registration Whether attached to a standardized pallet or not, a kinematic mount enables extremely precise and rigid mounting of a workpiece onto a workstation.

Contact us

|