|

Download:

|

Spherolinder Kinematic Mount

The Spherolinder Kinematic Mount is our original product. Capable of carrying up to 1900 kg per each M25 mount element, or 300 kg per each M10 mount element. It is our highest load capacity product for a given connector size.

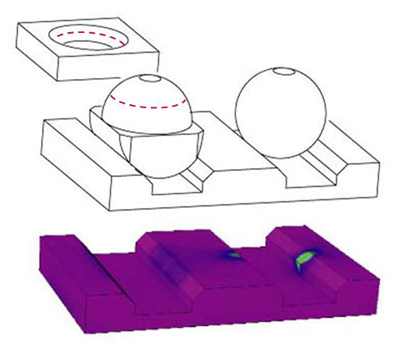

The mount integrates with your design as shown on the right. The components to be mated kinematically are colored Red and Blue. The three Spherolinder mating elements are silver, and are embedded into the mated parts at three points. The mount is based on the Spherolinder solid object (shown on the left), whose patented shape is a concentric concatenation of a half-sphere and a half-cylinder. (The center of the sphere lies on the axis of the cylinder)

The Spherolinder Mount is derived from the classic 3-groove mount by replacing each sphere-in-groove mating element with a cone-Spherolinder-groove mating element, as shown on the left. The resultant mating element is kinematically equivalent to a sphere-in-groove, but since it eliminates point contacts in favor of line contacts, it has a load capacity roughly 100 times larger (compared to a sphere of the same diameter). A complete mount is constructed using three Spherolinder mating elements, with their axes pointed roughly towards their common center, as shown above. (There is no special requirement for positioning the mounting elements accurately.) If the load is distributed equally among the three elements, the total static load capacity of the mount is three times that of each of the individual mating elements.

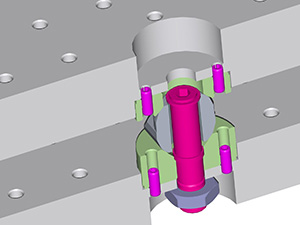

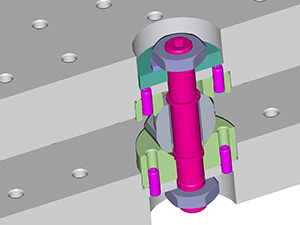

Special retainers ensure that the Spherolinder body is constrained within the V-groove, but free to move. In the "through" version of the mount, these retainers extend through the cone blocks and allow you to pre-load the two components to each other (using compliant bellevile washers) through the center of the Spherolinders. This version is intended for vertical, tilting or dynamic-load applications. In the "blind" version of the mount, the retainers are shorter, and the mount relies on gravity or on an external means for ensuring the components do not separate. This version is intended for horizontal and static applications, or where an external retaining mechanism is used.  M05, M10, M25, M50

M05, M10, M25, M50(Tape marked in inches)

Standard stock spherolinder sizes are M10 and M25, and are made from 58Rc hardened Stainless Steel 440C. Custom units can be made between M5 and M50, and from several engineering materials. Load limits are stated using a 100% safety margin over the calculated Herzian yield stress, for the static horizontal position. For properly pre-loaded vertical or tensile mounts, the load capacity is halved. |

| 650-605-4500 | ©2017 g2-engineering |

Blind

Blind

Thru

Thru